Kontaktoplysninger

200 meter øst for Xihuang Landsbykomité, Linchi By, Zouping By, Binzhou By, Shandong Provins (Kina)

Her er hvorfor flervævsstof er et fremragende materiale til medicinske anvendelser. I modsætning til traditionelle stoffer, som er vævet sammen, fremstilles flervævsstof ved limning gennem varme, kemikalier eller mekaniske processer. Som følge heraf er flervævsstoffer meget åndbar og kan tillade luft og fugt at passere igennem, mens de alligevel holder støv og mikroorganismer ude. Åndbarheden er især vigtig for medarbejdere i sundhedsvæsenet under lange vagter, der bruger kirurgiske masker og kittler. Flervævsstoffer er også meget holdbare og kan have høj trækstyrke, hvilket forhindrer forurening af medicinsk materiale. Deres andre egenskaber gør dem ligeledes ideelle til brug i sundhedssektoren.

Ikkevævedes vigtige barrieregenskaber hjælper med at forhindre mikrobiel forurening, hvilket er et hovedfokus i sundhedssektoren. Brugen af ikkevævet stofteknologi gør det muligt at konstruere barriermaterialer, der kan forhindre passage af bakterier, virusser og andre mikroorganismer.

Dette gælder for engangs medicinske produkter som kirurgiske dukker og sårforbindinger. Disse genstande kommer i kontakt med patienters sår eller kirurgiske områder. Den tætte fiberstruktur i ikke-vævede materialer skaber en fysisk barriere, der hindrer mikroorganismer i at trænge igennem stoffet og derved reducerer risikoen for infektion. Desuden er mange typer af ikke-vævede materialer, der anvendes i medicinske miljøer, behandlet med antimikrobielle midler. Disse midler bruges til yderligere at forbedre stoffets modstand mod mikroorganismer og mindske risikoen for krydscontamination mellem patienter og sundhedspersonale. Genanvendelige stoffer kan indeholde mikroorganismer, som rengøring ikke fjerner, mens ikke-vævede produkter er enkeltbrugsartikler. Dette eliminerer risikoen for resterende forurening fra tidligere brug og gør ikke-vævede materialer til et sikrere valg til kritisk medicinsk brug.

Når ikke-vævet stof anvendes til medicinske formål, er dets komfort og biokompatibilitet meget vigtige. Når medisinsk personale bærer ikke-vævede produkter i lange perioder, som rengøringsdragter og ansigtsbeskyttelser, er komforten afgørende. Ikke-vævet stof har en blød og glat struktur, der føles behageligt mod huden.

Dette er især relevant for patienter med følsom hud, som måske bruger ikke-vævede produkter til sårvård over længere tid. På grund af sin struktur og sine bløde plejegenskaber for følsom hud er ikke-vævet stof mere hudvenligt. Det er desuden ikke-irriterende, hypoallergent, ikke-toksisk og frit for bekymrende stoffer, der kan udløse hudproblemer. For eksempel er ikke-vævet gaze, der anvendes i sårforsband, hypoallergent og designet til at ligge behageligt i kontakt med åbne sår uden at hæmme helingsprocessen. Biokompatibilitet og komfort kombineres for at mildne den grovhed og stress, der ofte er forbundet med ikke-vævede materialer.

I medicinske omgivelser forbedrer ikke-vævet stof både omkostningseffektiviteten og muligheden for engangsbrug, hvilket giver en væsentlig værdi. I sundhedsplejeydelser, hvor der kræves strenge infektionskontrolforanstaltninger, betragtes engangsbrug af anvendte produkter som den primære metode til at undgå krydscontamination. Finansielt set er det billigere at producere ikke-vævede materialer i forhold til vævede og strikkede tekstiler, da det muliggør økonomisk massedannelse af engangstekstiler til medicinske formål. For eksempel er det billigere at producere engangsgesigtsdække, handsker og sengetøj i store mængder ud af ikke-vævet stof frem for at betale for genanvendelige varianter.

Desuden, da du kan kassere ikke-vævede materialer efter brug, behøver du ikke bekymre dig om tidskrævende og kostbare rengørings-, steriliserings- og vedligeholdelsesprocedurer, som er forbundet med genanvendelige tekstiler. Rengøring af genanvendelige medicinske tekstiler indebærer vask ved høj temperatur, brug af specielle rengøringsmidler og efterfølgende sterilisering gennem autoklavering, hvilket er ret kostbart og arbejdskrævende. Sundhedsinstitutioner kan spare tid og arbejdskraft samt driftsomkostninger ved at anvende engangsprodukter af ikke-vævet materiale, samtidig med at de opretholder de krævede sanitære standarder.

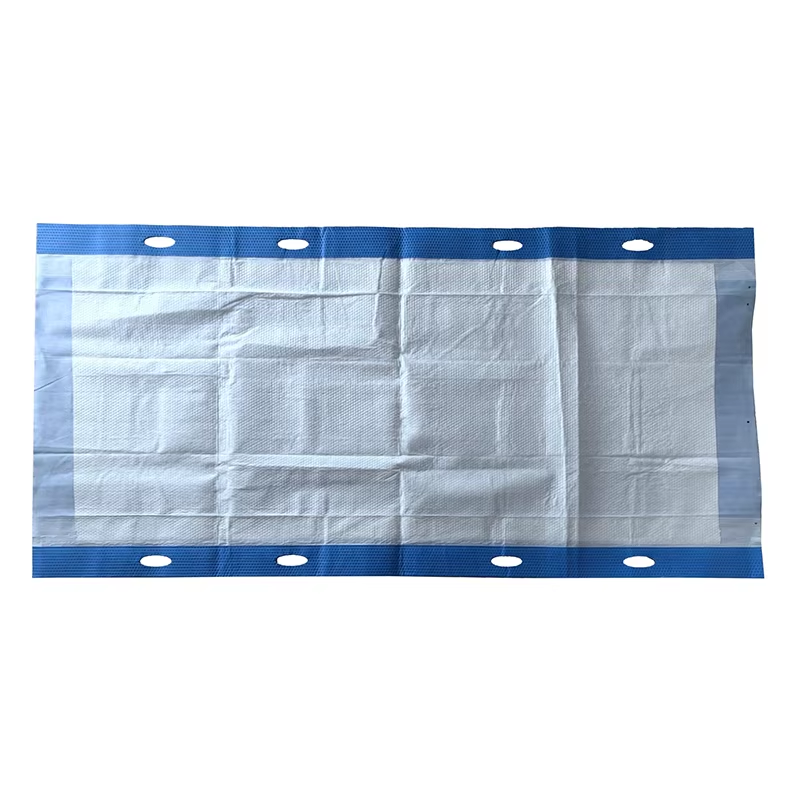

Ikke-vævet materiale kan være et alsidigt og fleksibelt sundhedsplejemateriale med mange anvendelsesmuligheder og stor værdi inden for sundhedssektoren, da de fleste af dets egenskaber kan ændres under produktionen. Personale i sundhedssektoren har forskellige behov, og ikke-vævede stoffer kan fremstilles med varierende tykkelse, absorptionsevne og barrierefunktioner. Ikke-vævede stoffer, der bruges til operationsklæder, er tykkere for at yde bedre beskyttelse mod væskegennemtrængning samt at sikre komfort, mens det ikke-vævede materiale til lette ansigtsmasker er tyndere og mere åndbart. Derfor kan ikke-vævede materialer bruges til fremstilling af en række medicinske produkter såsom operationslåger, sårforbindinger, inkontinenspadde og medicinske tørrevisker. Hvert af disse produkter har forskellige funktioner, og ikke-vævede stoffer kan udformes for at opfylde de nødvendige specifikationer.

Tag for eksempel tilpasning af ulovende sårforbindinger, så de er ekstra absorberende, eller design af ulovende medicinske tørreklæder, der er fri for flint, og ikke efterlader noget råd på følsomt medicinsk udstyr. Denne slags alsidighed gør ulovende materialer afgørende for udviklingen af en række effektive medicinske produkter.

Ikke-vævede materialer opfylder standarder for sundhedssektoren, hvilket øger deres uantvist accept inden for branche. Ikke-vævede medicinske materialer overholder standarder fastsat af FDA og ISO med hensyn til sikkerhed og ydeevne, branchematerialer samt mikrobiel barrierefunktion og biokompatibilitet af produkterne. Producenter af ikke-vævede materialer viser bevidsthed om standarder ved at sikre kvaliteten af råmaterialer og kontrollere produktionsprocessen. Ved sterile medicinske produkter fremstillet af ikke-vævede materialer arbejder producenter under rengøringsrumskonditioner for at undgå forurening, og produkterne testes for barriereegenskaber, sikkerhed, væskebestandighed, mikrobiel filtrering samt fravær af skadelige stoffer.

Ved at følge disse strenge normer sikrer ikke-vævede materialer, at sundhedsytere kan have tillid til, at de produkter, de anvender, er sikre, pålidelige og effektive til patientpleje.