Contact Info

200 meters east of Xihuang Village Committee, Linchi Town, Zouping City, Binzhou City, Shandong Province (China)

In healthcare, using absorbent products properly is essential for patient comfort, infection control, and efficient healthcare procedures. As an ISO13485 and CE certified organization, Mepro Medical Tech Co Ltd is a reputable manufacturer of quality medical materials, including absorbent products. These products are certified to meet medical requirements and produced using high performance industrial grade additive manufacturing of metals. This article explains the application of absorbent products in healthcare and their link to additive manufacturing of metal materials.

In wound care, absorbent products are essential. They serve to absorb wound exudates, which consist of blood and tissue fluid, to keep the wound area dry and clean, promoting healing and preventing infections. Mepro Medical offers hydrophilic non-woven fabric with good air permeability and no skin allergies. This fabric is commonly used as a core component in wound dressings. During production, the molds used to process this absorbent fabric are created using Industrial grade additive manufacturing of metal materials. The metal molds created using this technology are very precise, which guarantees the absorbent fabric uniform construction, and predictable, stable absorbent characteristics. For instance, in the care of surgical incisions or traumatic wounds, medical personnel will cover the wound with Mepro's hydrophilic non-woven fabric absorbent dressings. These dressings quickly absorb exudates and maintain a dry environment around the wound to decrease bacterial growth.

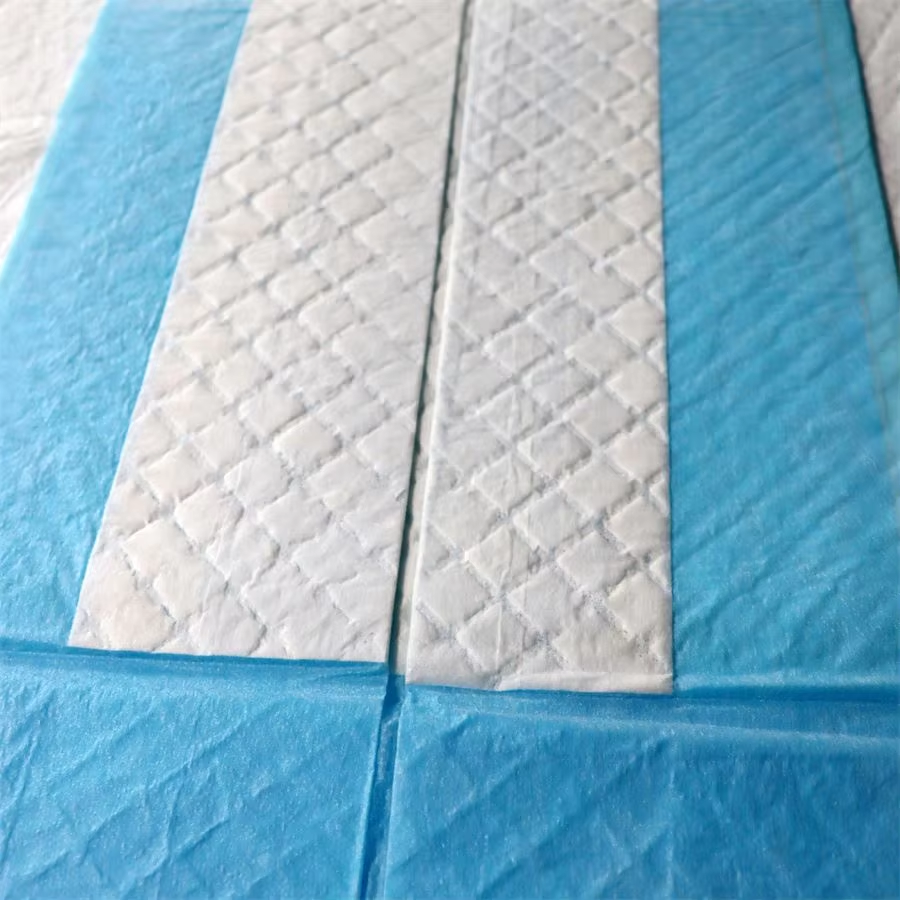

In daily patient care especially for bedridden patients or those with incontinence absorbent bed sheets and disposable underpads. Mepro Medical's SMS polypropylene non woven fabric is an ideal material for such absorbent products. Mepro Medical's SMS polypropylene non woven fabric is an ideal material for such absorbent products. It has a multi layer structure that enhances water resistance and absorbent capacity. The production equipment of this SMS non woven fabric such as the rollers used for pressing and forming relies on metal parts manufactured by additive manufacturing. These metal parts have high wear resistance and stability ensuring continuous and efficient production of absorbent materials.

In hospitals bedridden patients use bed sheets made of this absorbent fabric which can quickly absorb sweat or other body fluids to keep the patient’s skin dry and comfortable. This prevents the bed from getting wet and reduces the frequency of bed sheet replacement.

Absorbent products are crucial during surgical operations because they help in keeping the surgical field clean and the operation moving smoothly. These products soak up blood and other liquids that can impair the surgeon’s sight and may lead to cross-infection. Mepro Medical’s 100% polyester needle punched non woven polyester fab improves strength and durability and is frequent in the production of surgical towels and surgical wipes. The production of this absorbent poly fabric did and still does the absorbent poly fabric cutting and shaping tools out of metal using additive manufacturing. The poly fabric cutting tools edge and metal precision allow the absorbent fabric to be cut in diverse sizes and shapes based on the fabric surgical needs. For instance, during abdominal surgery, the medical staff uses towels made of this absorbent fabric and lays them around the surgical site to absorb blood and keep the surgical area clean, providing a good operating environment for the surgeon.

Healthcare settings positively utilize infection prevention absorbent products. Infection prevention absorbent products utilize the antibacterial property of liquid absorbing materials. This reduces cross infection. Mepro Medical disposable isolation gowns, made of high quality non woven fabric which sometimes has absorbent layers. This absorbent layer protects the skin of the medical staff by absorbing splashed body fluids or medical fluids, preventing splash penetration through the gown. The isolation gowns production process adheres to the assembly of multiple layers isolation gowns materials. The assembly line includes metal fixtures positioning which are designed using additive manufacturing. The precision of these fixtures means the isolation gowns will be accurate in their absorbent layer positioning as well as maintaining their position during use. Medical staff in infectious disease wards utilize absorbent layer isolation gowns which effectively reduces infection risk when splashed body fluids are present.

Some connections between the healthcare industry and the industrial grade additive manufacturing for metal materials include the use of advanced manufacturing technologies to create absorbent healthcare materials. Specifically, the technology is used to produce high precision metal molds and components for manufacturing equipment and production line machines. Note that some of the metal components described earlier, which include the molds for hydrophilic non woven fabric and rollers for SMS non woven fabric production, are metal additive manufactured components. The use of advanced technology metal components directly influences the quality and production efficiency of absorbent materials. New technologies are also developed through additive manufacturing to create innovative structures for potential new types absorbent products. For instance, Mepro Medical can design shaped metal nozzles through metal additive manufacturing that can spray absorbent coatings and apply them uniformly to non woven fabric. Improving the absorbent capacity of non woven fabric is essential as it is the main component of many healthcare products and materials. This type of integration increases the functionality of healthcare absorbent materials and also accelerates the innovative design and development of healthcare materials.

Without question, safe and effective absorbent products need to be controlled during every step of use in the health care field. Quality Control Systems that encompass ISO13485 all stops hold Mepro Medical to the industries best standards, when it comes to testing products, mastering the testing in absorbency, durability, and biocompatibility is order. The sensors that measure the speed of absorbent materials are made of metal components manufactured using additive manufacturing. The precision of test absorbent materials last robotic sensors and test endurance results are the reason test results are reliable. Moreover, Mepro Medical is developing more absorbent products using sustainable and eco friendly absorbent materials, like recyclable polypropylene non woven fabric. Environmentally sustainable eco friendly absorbent products use energy efficient and additive manufactured metal designed to reduce energy use, energy consumption in the ecosystem, and the environment. Mepro Medical can achieve better results in improving the quality of medical care with absorbent products developed using sustainable eco friendly methods.